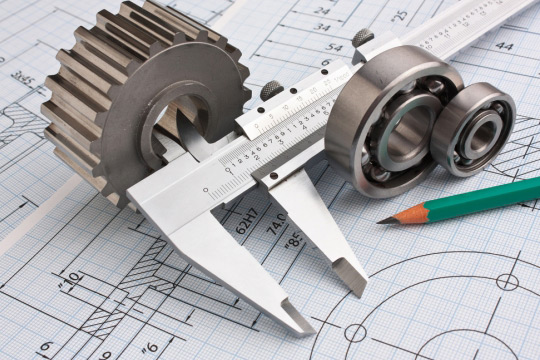

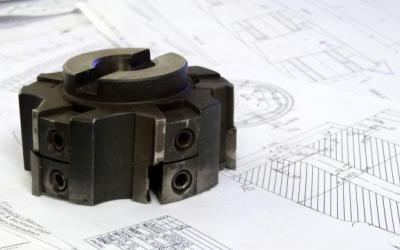

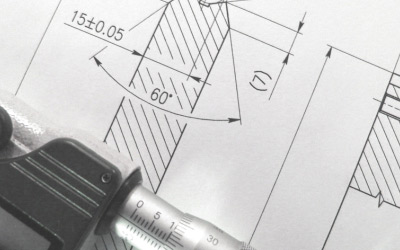

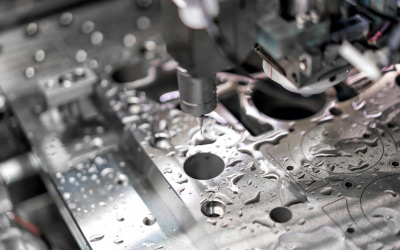

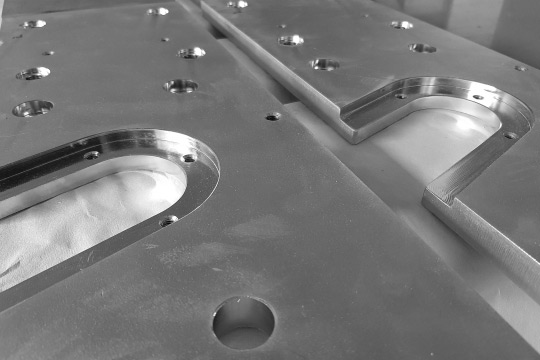

We operate a comprehensive range of modern technology, from conventional equipment to CNC technology with devices for thermally clamping machine tools and assembly of oversized parts and subgroups. Our machines allow indexed and smooth 5-axis milling with an accuracy of 0.005 mm. With this technology, we can mill diverse surfaces and shapes according to the customer’s requirements.

Our technologies let us provide comprehensive services, from cutting operations to final finishing of assemblies of single-purpose machines and equipment. Production is prepared and optimized on modern CAD / CAM systems.

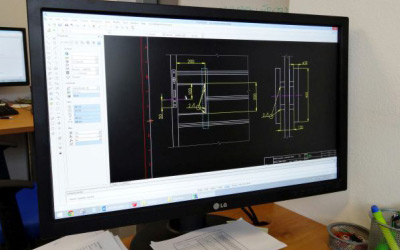

Our customers receive technical support, such as 3D product model development and assembly, drawing production documentation and producing accompanying process and technological documentation. Our employees work with the latest AutoCAD, SolidWorks and Visi software. Designing and optimizing production is done with SolidCAM and SolidEdgeCAM CAD / CAM systems. Production itself is controlled with production management software.

Our designers and engineers

in the design and development department of ICT Slovakia

use the latest AutoCAD, SolidWorks and Visi software.

We offer materials cutting services with circular and band saws up to 250 mm in diameter. We can customize cut sheet materials with formatting saws and cut shapes on sheets with laser machines.

We operate a comprehensive range of modern technology, from conventional equipment to CNC technology with devices for thermally clamping machine tools and assembly of oversized parts and subgroups.

Our machines allow indexed and smooth 5-axis milling with an accuracy of 0.005 mm. With this technology, we can mill diverse surfaces and shapes according to the customer’s requirements.

Our technologies let us provide comprehensive services, from cutting operations to final finishing of assemblies of single-purpose machines and equipment.

We prepare and optimize production on modern CAD / CAM systems.

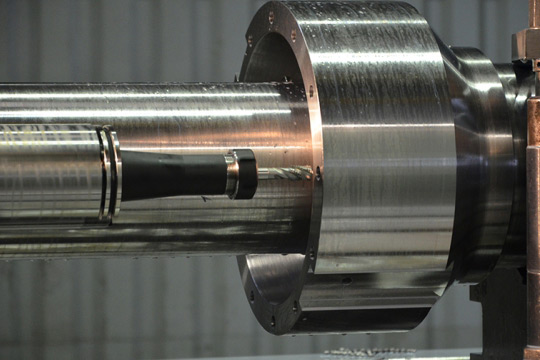

We machine parts on very precise CNC lathes and MORI SEIKI milling machines but also use conventional methods. Our equipment can work mechanically with parts up to 5000 kg in weight.

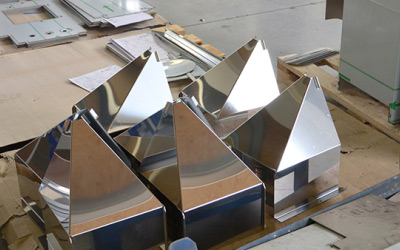

We bend and fold individual items of various materials, types and thicknesses, including entire series. Using our modern TRUMPF TrumaBend C66CNC press brake, we can bend sheet metal up to 2000 mm in length and 5 mm in thickness.Realizujeme ohýbanie a ohraňovanie jednotlivých kusov rôznorodých hrúbok, materiálov a typov až po celé série. Pomocou moderného CNC ohraňovacieho lisu TRUMPF TrumaBend C66 dokážeme ohýbať plechy až do dĺžky 2 000 mm a hrúbky 5 mm.

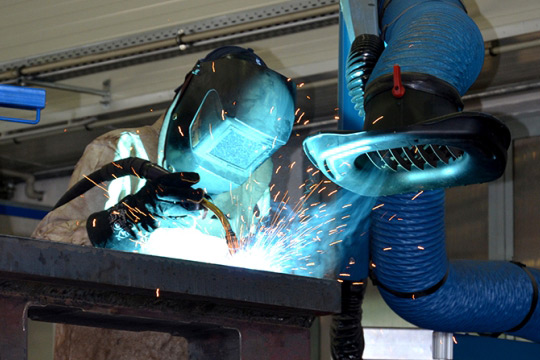

All kinds of steels, stainless steels and aluminium alloys are welded in our welding plant by certified welders. We weld using MIG / MAG, TIG / TIG, soldering and flame on a range of small sheet metal and machine parts, medium-sized stainless steel and aluminium constructions, and large weldments up to 5000 kg in weight.

We offer sandblasting and granulation. We can customize surface treatment with powder coating, hot-dip galvanizing, nickel-plating and blackening.

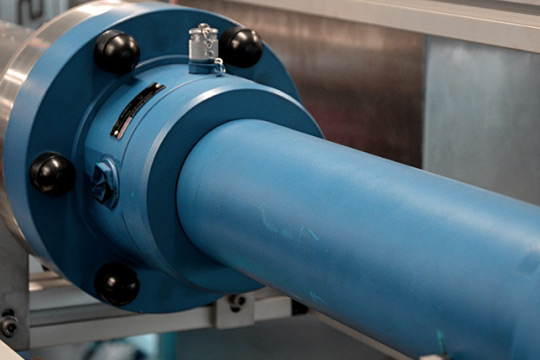

We operate an assembly workshop with professional staff, equipped with modern technology for mechanical, electrical, pneumatic and hydraulic assembly.

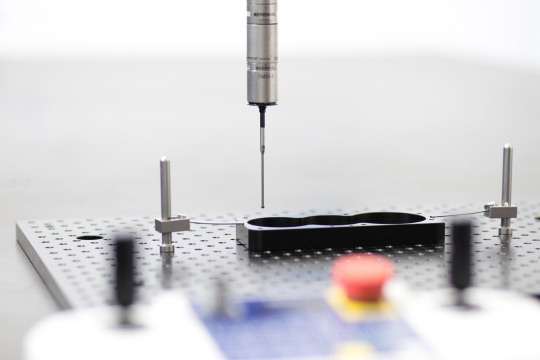

Final inspection is conducted with the most advanced 3D CNC coordinate measuring machine – CRYSTA APEX S122010 from MITUTOYO.

The machine has a measuring range of X: 1200 mm Y: 2000 mm Z: 1000 mm. Measurement accuracy (2.3 + 3.0 * L/1000) μm. Max. workpiece height 1200 mm. Machine table capacity 2500 kg.

The company is currently expanding production and investing in technological innovations. With modern design and development departments and state-of-the-art production and assembly workshops, our qualified and technically skilled personnel reliably meet our customers’ quality and quantitative needs.

We are continually modernizing our machinery. Our current services and technology portfolio is now available in a new, clear PDF version: